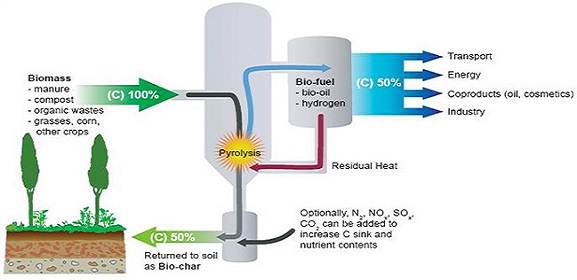

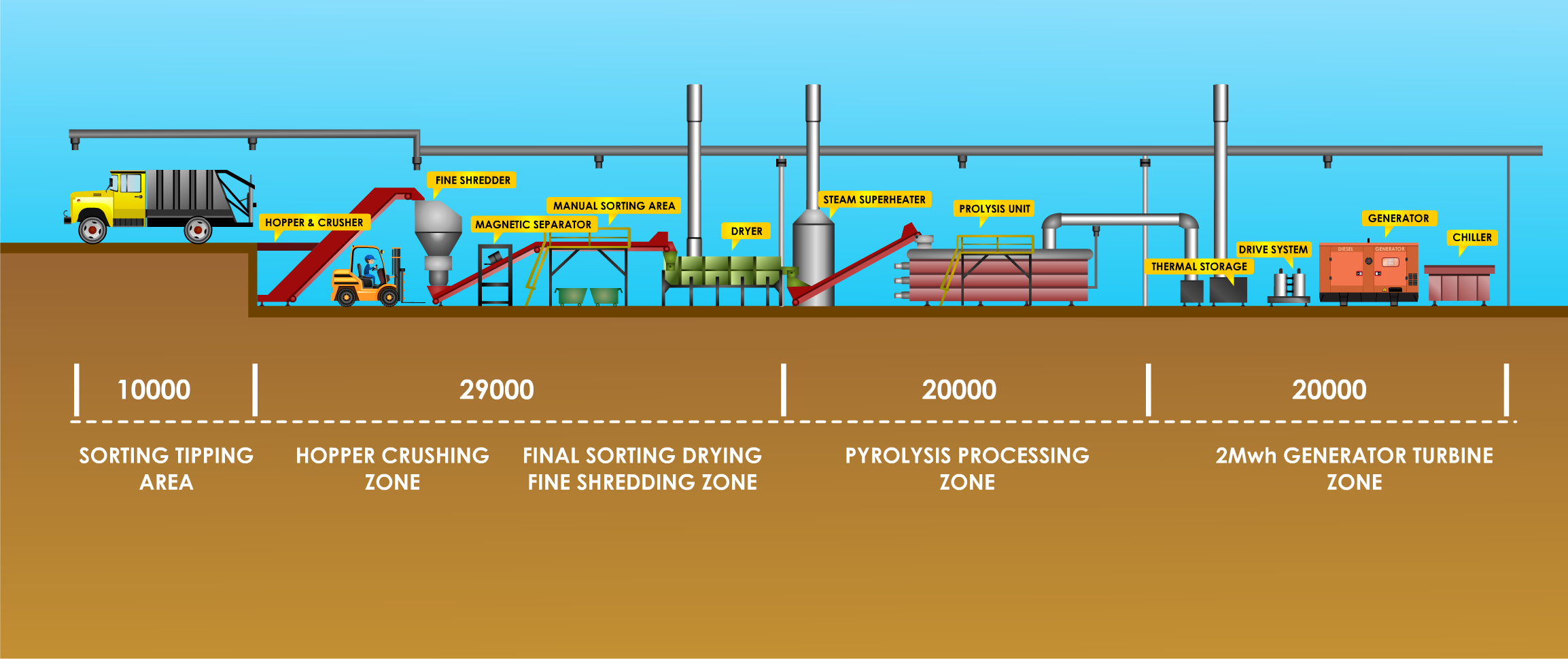

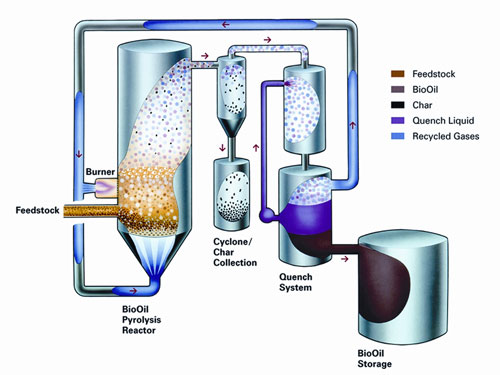

Pyrolysis is the thermal decomposition of complex organic matter in the absence of oxygen to simpler molecules that can be used as feed stocks for many processes. The main products produced by the pyrolysis process are activated carbon, diesel and syn-gas.Pyrolysis consists of a endothermic reaction. General combustion occurs through the generation of heat in the Pyrolysis chamber producing solids and liquids. The feedstock is heated at moderately high temperatures in a low oxygen atmosphere. Diesel produced by this pyrolysis process can be used purely as a fuel, or for other related end products. The syngas produced in used for the pyrolysis combustion process and to run the power generation turbine(s).

The biomass used in pyrolysis is typically composed of cellulose, hemi-cellulose and lignin. The main parameters that govern the pyrolysis process are temperature, heating rate, solid residence time, volatile residence time, particle size and density of particles.

The products produced in the process vary and depend on the feedstock type i.e., cellulose material and some biomass produce bio-char and activated carbon. Mixed Residual Waste (MRW) and Municipal Solid Waste (MSW) feedstocks produce Diesel and Electricity and a small amount (10% of weight) of inert ash. MSW feedstock processed in our pyrolysis technology transforms hazardous materials into a number of main products such as activated carbon, diesel and syn-gas.

Syn-gas, or synthetic gas, is the name given to volatile gas that has been created by the pyrolysis chamber and containing varying amounts of carbon monoxide and hydrogen.

The syn-gas produced is used to power both the generation turbine(s) and the Pyrolysis Plant.

Electricity generated from 20 tonnes of waste per day, using the syn-gas method will supply 2 MW of green renewable energy supplied directly to the national or state electricity grid. Using the latest power generation technology, we are able to maximise returns in Energy Generation.

Consisting of chemicals with a wide range of molecular weight distribution that can be used as a direct replacement for Standard Diesel used in energy generation among other usesd. Using the latest power generation technology, we are able to maximise returns in Energy Generation. The syn-gas produced is used to power both the generation turbine(s) and the Pyrolysis Plant.

One of the unique aspects of our Pyrolysis Technology is that it will create 10,000 litres of euro grade green diesel every day, seven days a week, 50 weeks a year, using just 20 tonnes of suitable dry feedstock per day. The syn-diesel is refined to meet international fuel standards and can be used as a standard grade diesel. Electricity

Our Pyrolysis Plant only creates a very small amount of bio-char and this is a significant co-product of the pyrolysis process having properties similar to coke. At 23–32 GJ per tonne, pyrolysis bio-char has a higher heating value than many grades of coal and is a green fuel that is CO2 neutral.

Bio-char can be used as a substitute for other industrial fuels to produce the heat required for drying the feedstock and / or to supply heat to the pyrolysis reactor or in pelletized form can be fed into the boiler to generate further energy for electricity production.

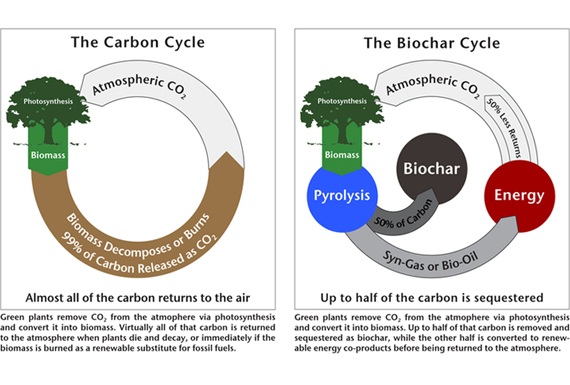

The addition of bio-char to agricultural soils is receiving much attention due to the benefits to soil quality and enhanced crop yields, as well as the potential to gain carbon credits by active carbon sequestration.